From April 4th to April 9th, 2023, Tsinghua University's Department of Industrial Engineering organized an Industrial Best Practice Immersion Class in Qingdao for international students from programs like International Master in Engineering Management (IMEM), Global Manufacturing (GM), RWTH Aachen, and Politecnico di Milano Double Degree Program. Led by Professor Yu Ming, Prof Liu Junyi, and Ms. Lu, the students had the opportunity to visit and learn from top-notch companies such as Qingdao Port, Hisense, TGOOD, Tsingdao Brewery Co. Ltd, FAW-Volkswagen Automotive Co. Ltd, and Aucma. The trip was a resounding success, providing students with invaluable insights into the manufacturing industry and the chance to engage in enriching discussions with senior executives of these enterprises. This experience will undoubtedly benefit the students for years to come.

Shandong University Reception

On the first day of arrival, the IE students had the honor of being welcomed by Shandong University, where they were introduced to the campus, the history of the university, and the programs of the School of Innovation and Entrepreneurship (SIE). They were greeted by a team of university professors, officials, and international students. A visit to the university museum was also organized, where the IE team was impressed by the modern architecture and large collection of cultural relics and ceramics. The museum visit allowed for interactions with fellow students of Shandong University, promoting cultural exchange and learning. Overall, the experience was unique and provided valuable insights into Chinese culture and history.

“We received a very warm welcome from Shandong University. I appreciated being able to visit another university campus in China. The first day was a unique moment for our immersion class because we were able to interact with our fellow students of Shandong University, allowing us to exchange more about our differences, in terms of cultures and studies, as well as, our common points, which is our Chinese experience away from home.” – Anna Amat, IMEM 2022

Fig1. Souvenir exchange between Professor Yu Ming (right) and Professor Song Chunling (left)

Fig2. Visiting Shandong University Museum

Fig3. Group Photo at Shandong University

Qingdao Port

On the second day, the IE team had the opportunity to visit two impressive ports in Qingdao. The first was the Qingdao Cruise Terminal, which was built in 2015 and used to receive cruise ships from various companies but has temporarily stopped due to the Covid-19 pandemic. However, it is being well-maintained and waiting for further policy changes to resume operations. The terminal has strict controls on food and passengers' medical status to avoid the spread of contaminants on board, even before the pandemic.

The second port they visited was the Qingdao Port, one of the world's seven largest container ports, and they saw Asia's first fully automated port, the Qingdao New Qianwan Container Terminal, in action. The port system consists of two types of cranes and electric vehicles that move containers between the two cranes. Gantry cranes are used to load and unload containers from ships, while rubber-tired gantry cranes move containers around the yard and deliver them to the gantry cranes for loading. The port also pioneered hydrogen-powered crane technology.

Qingdao Port has a capacity of 37 million containers and uses barcode or QR code technology to scan and identify the containers without the need for invasive inspection methods. The port's automated system is efficient and adaptable, and a pre-programmed navigation system facilitates the positioning of containers within the port, ensuring efficient handling and minimizing delays. Automated ports require a significant upfront investment in technology and infrastructure, but this pays off in the form of long-term savings and efficiency. Continuous innovation, research, and development are necessary to overcome the challenges of constructing and operating advanced port facilities like Qingdao.

“Our visit to Qingdao Cruise Terminal and Qingdao Port highlighted the advanced technology and automation that have been integrated into their operations. The fully automated QQCTN demonstrated significant increases in efficiency and adaptability, and the use of hydrogen-powered crane technology showed the importance of continuous innovation. To adapt to the evolving technological landscape of the port industry, we suggest investing in local workforce training and collaborating with other international ports to exchange best practices. This would further improve operations and position Qingdao Port as a global leader in port automation.” – Jerry Chong, IMEM 2021

Fig4. Qingdao Cruise Terminal staff explaining the structure of the cruise to the IE Team

Fig5&6. IE Students at Qingdao Port

Hisense

In the afternoon, students then visited the production facilities of Hisense, a multinational electronics company that produces and sells various consumer electronics and home appliances worldwide. We toured the air-conditioner and TV production, which were on the same premises. The AC production was highly automated, while the TV production factory size was smaller and characterized by small production steps and manual labor. We were impressed by the company's commitment to research and development, as well as its strategic partnerships and collaborations with other industry leaders, which play a significant role in the company's success.

After the visit to the production sites, we visited the Hisense headquarters in the city CBD area and were given a tour of the showroom by Dr. Remi Sham. We gained an overview of Hisense's product range and learned about the company's diversification strategy to expand globally. Hisense invests heavily in R&D, resulting in numerous technological advancements and a robust intellectual property portfolio. The company's innovative products range from laser TVs and smart meeting room displays to high-tech products for the future of transportation and the medical field. Overall, it was an inspiring day that provided great insights into potential future careers in the fields of logistics and technology.

“Hisense is a leading Chinese multinational electronics company that invests heavily in research and development (R&D) resulting in numerous technological advancements and a robust intellectual property portfolio. They have several R&D centers worldwide, and their strategic partnerships with industry leaders play a significant role in their success. Hisense's commitment to innovation and seeking new opportunities helps them maintain their position as a global leader in consumer electronics and home appliances. Our visit to Hisense provided great insights into potential future careers in logistics and technology.” – Leo Eychenne, IMEM 2021

Fig7. Group Photo at Hisense

TGOOD

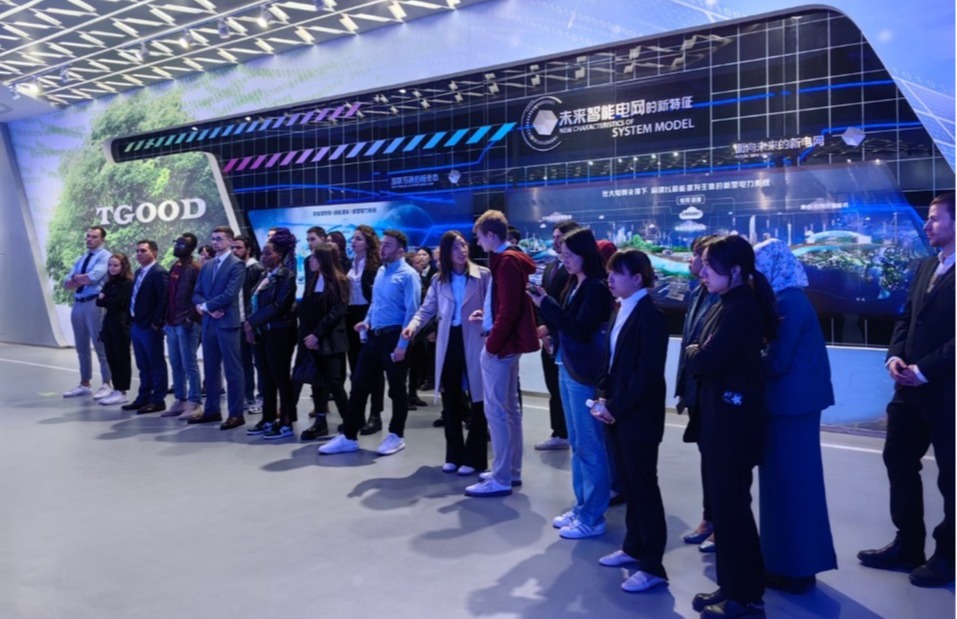

On the third day, students went to visit TGOOD, a leading company in the electric power equipment industry, specializing in the research, development, and production of high-quality electrical products and services. During our day trip, we were shown the production lines and assembly process for the company's various products, including transformers, switchgear, and power distribution equipment. TGOOD's products are used in a wide range of applications, and the company is dedicated to providing customized solutions to meet the unique needs of its customers.

TGOOD's global and national strategy focuses on expanding its presence in key markets around the world, including Europe, the Americas, and Asia, while working closely with the Chinese government to promote renewable energy sources and develop new technologies that reduce dependence on fossil fuels. Research and development are the key focus for TGOOD, and the company has established a state-of-the-art center to develop new products and technologies to improve the efficiency and reliability of electrical systems.

Since its founding in 2004, TGOOD has grown rapidly, thanks to its focus on innovation and customer service. Despite facing challenges in the competitive electric power industry, the company remains dedicated to investing in research and development, expanding its global reach, and maintaining its reputation for quality and reliability. IE Students found this visit to TGOOD a fascinating experience that gave them a first-hand look at the company's commitment to innovation, quality, and customer service, and a deeper understanding of the challenges and opportunities in the electric power industry today.

“During the Qingdao Immersion Class, I had the opportunity to tour TGOOD, a company that surprised me with its level of innovation. TGOOD produces highly innovative and relevant products, especially in the field of electric vehicles. I was impressed by the showroom, which showcased their cutting-edge technology.” – Alper Avci, RWTH Aachen 2022

Fig8. IE students listening to the introduction given by TGOOD staff

Tsingdao Brewery

In the afternoon, IE students went to the Qingdao Beer Factory. The tour includes a visit to the Tsingdao Beer Museum, where visitors can learn about the history of beer brewing in Qingdao and the German technological transfer that occurred in the early 20th century.

The history of beer brewing in Qingdao dates back over a century, with the establishment of the German Tsingtao Brewery in 1903. Today, the Qingdao Beer Factory is owned by Tsingtao Brewery Company Limited, one of China's largest beer producers. The brewery uses state-of-the-art equipment and techniques to produce beer, with a laboratory responsible for ensuring quality and consistency.

After the museum tour, visitors can explore the old Tsingdao factory, established in 1903 during the German occupation of Qingdao. The factory's architecture reflects its German origins, and visitors can see some of the original brewing equipment, including large copper kettles used for boiling the beer. The tour also includes a visit to the new, automated factory, which uses cutting-edge technology to produce beer on a large scale. Visitors can see the entire production process, from the raw materials being delivered to the final product being packaged and shipped out.

“At the Tsingtao Brewery Co. Ltd museum, it was exciting to learn about the history and development of the brand. The beer tasting was a highlight of the trip, and it was fascinating to see how the company has evolved over the years. Overall, I had a great time on the trip, and I gained valuable insights from visiting these companies. I am looking forward to seeing how they will develop in the future.” – Johannes Rother, RWTH Aachen 2022

Fig9. Students watching the introduction of Tsingtao Brewery

Fig10. Group photo at Tsingtao Brewery Museum

FAW-Volkswagen Automotive Co. Ltd

On Day 4 of the trip, the team visited FAW-Volkswagen Automotive Co. Ltd, a production site that plays a pivotal role in the production of Bora and Audi cars, known for its advanced automation and industrial engineering practices. At FAW-Volkswagen, the students had a guided tour and witnessed the four key steps of vehicle production: stamping, welding, paint shop, and assembly. They were amazed by the level of automation employed throughout the Qingdao factory and had the honor of attending a presentation and discussion session with Mr. Chen, the expert in car automation production and the person responsible for industrial engineering at the factory.

Mr. Chen provided insights into the factory's efficiency control management, workshop flow, and the significance of optimizing production flow through advanced automation and management techniques. FAW-Volkswagen utilizes the latest measurements and tools for analyzing their industrial efficiency and implementing the 3P strategy. The site utilizes the MTM methodology, the API industrial technology system for design and production, the VSM process for problem-solving, and digital platforms with analytical systems for data collection and analysis of employee work to improve production rate efficiency.

The level of automation and the prowess in industrial engineering was top notch, the plant took into consideration so many issues and concerns from the supply chain, production process, and rate to the site's employee impact and technology concerns.

“FAW-Volkswagen could explore even more innovative production techniques to optimize its manufacturing processes if it wishes to maintain its position as the industry's dominant player. One option is to implement Industry 4.0 technologies, such as AI-powered automation, and digital twins, to optimize their production lines and increase overall efficiency. FAW-Volkswagen can create more sustainable and cost-effective manufacturing solutions by utilizing these cutting-edge tools, thereby increasing its market competitiveness. In addition, the company could consider forming strategic partnerships with suppliers to secure long-term access to vital resources, such as batteries and specific metals for electric vehicles, to meet future production needs.” – David Pongrac, IMEM 2021

Fig11. IE students listening to the brief introduction by FAW-Volkswagen staff.

Fig12. Group photo at FAW-Volkswagen Automotive Co. Ltd

Aucma

During their visit to AUCMA in the afternoon, IE students had the chance to explore their freezing technology and understand their engineering design process. The Center for Design and Research and Development showcased various freezing applications and innovations in the field. We learned that AUCMA specializes in a wide range of freezing technology, from residential freezers to high-tech cold chains for medical and vaccine storage, as well as advanced IoT freezers and washing machines. One of the most impressive products was the AUCMA's MetaFridge Vaccine refrigerator which tackled the challenge of keeping vaccines at the right temperature with poor power availability, making it a key factor in the health systems of low-income countries. The executives highlighted the company's commitment to innovation and its focus on meeting the evolving needs of customers through advanced engineering design and research.

The team also had the opportunity to engage with AUCMA's executives and ask them about the company's rapid growth and competitive edge. They shared valuable insights into AUCMA's business strategies, emphasizing the importance of continuous improvement in production processes and the adoption of cutting-edge technology to stay ahead in the market. AUCMA's dedication to online e-commerce and international marketing was also highlighted as a key element of its growth strategy.

The visit to AUCMA was insightful and inspiring, allowing IE students to witness first-hand the company's innovative approach to freezing technology and its dedication to excellence in production and engineering design. They were inspired by AUCMA's commitment to staying at the forefront of the industry through continuous improvement, technological innovation, and customer-centric strategies.

“AUCMA has a very good production plant which also includes some automation processes, we believe that they have overcome different challenges throughout their history, as listened to during Q&A sessions, some solutions were not measured, we believe that to maintain the good work, the company should use different methodologies such as PDCA, plan, do, check and act, in addition to continuous improvement concepts which will help them understanding the problems, understanding the solution, but most importantly, keep innovating and solving any issue that might arise in the future.” – Jorge Martinez, IMEM 2022

Fig13. Students Visiting Aucma Laboratory Headquarters

Fig14. Aucma staff introducing various products to IE students

Fig15. Dialogue between Aucma executives with IE Students

Laoshan Mountain

On their last day in Qingdao, the IE team took a break from company visits and explored the breathtaking Laoshan mountain area. As the highest mountain along China's coastline, Laoshan is not only a natural wonder but also an important symbol of Taoism. They were led by an enthusiastic guide who provided us with interesting insights and took us to scenic spots, including some of the palaces, temples, and nunneries that were once located there.

The team also had the opportunity to explore the Mitian cave, a thrilling narrow cave that led us to one of the most astonishing views of the area, the Yankou scenic spot. The image of Yankou Bay, imposing canyons, and undulating peaks was a breathtaking sight and a perfect way to end our trip. As they hiked through the mountain, they gained a deeper appreciation for the natural beauty of the area and the importance of Laoshan in Chinese culture.

Overall, the Qingdao Immersion Class was a huge success, giving them access to see the way of production in the visited manufacturing plants and have enriching discussions with senior executives of those companies, for which they express their gratitude to Professor Yu, Professor Liu, Ms. Lu, Tsinghua Industrial Engineering Department, Shandong University, and the host companies.

“I think that the last day of our trip to Qingdao was a very good finish for the whole trip. The hike at Lao Shan was relaxing and introduced us to a different side of Qingdao. Before we mostly saw the strong industry in the region. The contrast to the wonderful nature was therefore very astonishing. It seems that Qingdao can combine a world-class industry with the beautiful environment surrounding it. This does not only increase sustainability but also makes the region more attractive to live in.” - Alexander Niklas, RWTH Aachen 2022

Fig16. Group photo in front of the “寿” character at Laoshan Mountain

Fig17. Group photo at the top of Laoshan Mountain

Contributors: IE students attending the Qingdao Immersion Class

Editors: Bernard Lee, Haitao Wang, Zixin Wang

Photographers: Timothe Lafon, Simon Eckelt, Jerry Chong

Reviewers: Liang Ma, Zhizhong Li